Tổng hợp các hình thức gia công hộp giấy nổi bật hiện nay

- Đăng lúc 23-10-2024

- Nguyễn Hoàng Nam

Currently, the printing and packaging industry is growing with many diverse forms of paper box processing , suitable for the aesthetic and usage needs of each business. Therefore, choosing the appropriate form of paper box processing not only helps to increase the value of the product but also creates a strong impression on customers. To learn more about the most prominent paper box processing methods, follow Hoang Gia Printing in the following article.

Current demand for printing paper boxes

The demand for printing paper boxes is currently increasing strongly due to the development of the consumer market and e-commerce. Businesses not only focus on product quality but also pay special attention to packaging, because paper boxes are not only a means of protecting products but also an effective brand promotion tool.

A product contained in a beautifully printed, professionally designed paper box will certainly stand out more, attract customers’ attention and contribute to building a more prestigious image of the business.

Therefore, businesses from large to small are now tending to invest more in printing paper boxes, from high-end product boxes to simple but sophisticated box designs. This has created an increasing demand for paper box printing and processing services in the market today.

Popular forms of paper box processing today

The forms of paper box processing are increasingly diverse and modern, helping businesses have many options to create impressive packaging, attracting customers. Below are a few suggestions for everyone to refer to:

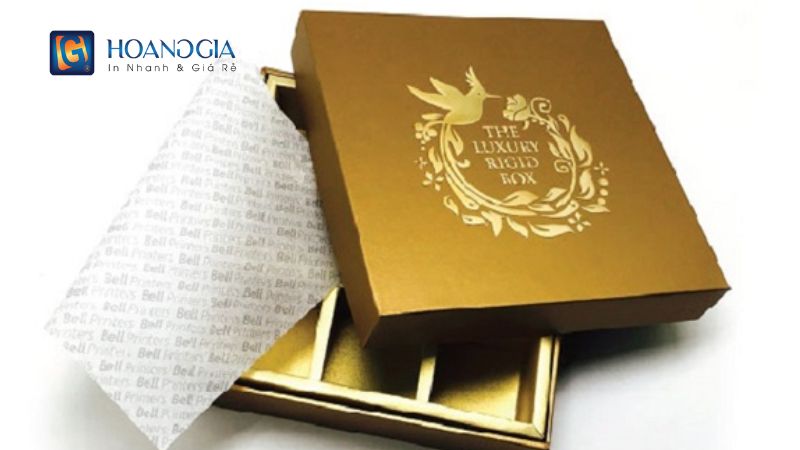

Paper box processing by embossing technology

Embossing is a method of using pressure to create raised patterns or logos on the surface of paper boxes, increasing aesthetics and helping the brand stand out. This technique is often used to highlight logos, important messages or special details on the packaging. Embossing not only brings a high-end feel but also creates a deep impression in the eyes of customers.

Processing by lamination technology

Laminating technology is a technique of covering a thin layer of film on the surface of a paper box to protect, increase durability and aesthetics. Currently, there are two popular types of laminating:

- Matte lamination: This technique makes the surface of the paper box smooth and elegant, without affecting the original color or design, but creates a more luxurious and sophisticated effect.

- Glossy lamination: This method uses a layer of glossy plastic film, which makes the surface brighter, while maintaining the original shape and color. The glossy film gives an eye-catching feel and increases the product’s ability to protect against external influences.

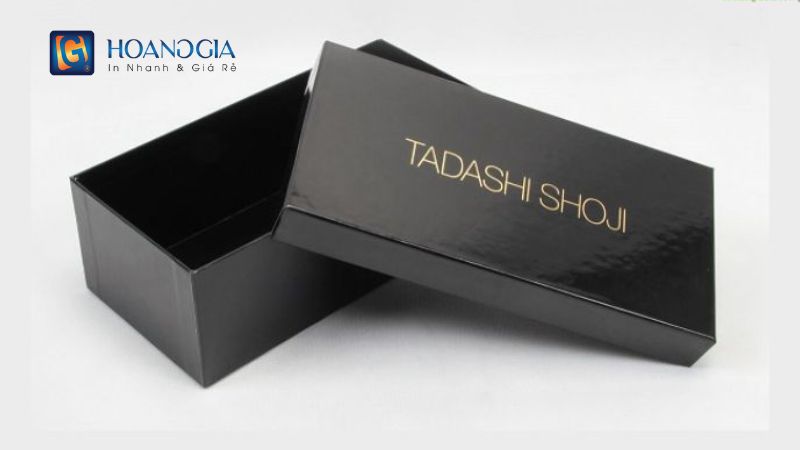

Processing by metal stamping technology

Foil stamping is a processing technique that uses metal foil (gold, silver or other colors) to create a luxurious highlight for packaging. Thanks to the combination of temperature and pressure, this technology brings a classy appearance, very suitable for high-end products such as cosmetics, gifts or jewelry. Foil stamping technique helps the product become more prominent, attracting attention at first sight.

Paper box processing with die-cutting machine

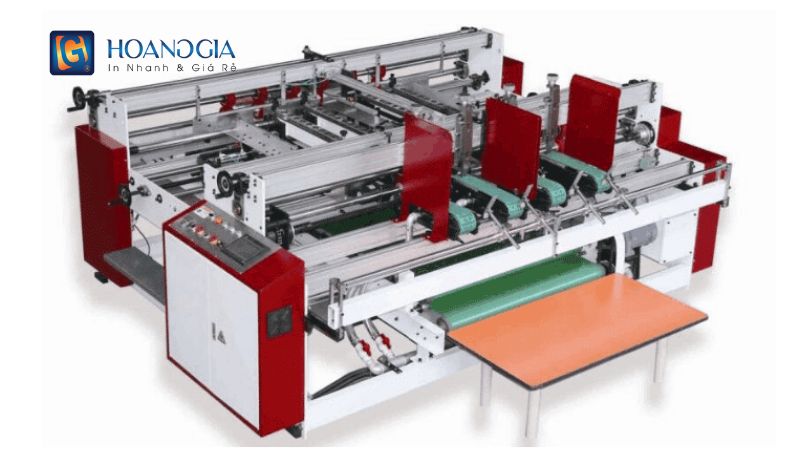

Die cutting is done using a die cutting machine to cut and shape the paper box according to the desired design. There are two common types of die cutting machines:

- Die cutting machine: Suitable for small orders, die cutting machine helps to cut boxes accurately and in detail, especially for products that require high sophistication. This process helps save costs and time for small quantity orders.

- Automatic die cutting machine : For large orders, automatic die cutting machine is an effective solution thanks to its fast speed and high accuracy. The machine helps increase productivity, ensure uniformity and minimize errors, thereby reducing production costs and processing time for large orders.

Processing with box gluing machine

After cutting and die-cutting is completed, the box gluing process is carried out using the following gluing machines:

- Semi-automatic Sealer: Ideal for small to medium-sized orders, semi-automatic sealers complete the box sealing process quickly and accurately. This method is suitable for products that require finesse, but do not require large-volume production.

- Automatic labeling machine: For large orders with requirements on progress and quantity, automatic labeling machine helps optimize the production process, increase productivity while ensuring consistent quality. This not only shortens production time but also reduces labor costs, quickly meeting all customer requirements.

Hoang Gia Printing – A reputable paper box manufacturing address in Hanoi

Hanoi is one of the largest economic centers in the country, with an increasing demand for printing and processing paper boxes, as businesses are always looking for beautiful, quality packaging to make a strong impression on customers. Understanding that, Hoang Gia Printing brings optimal packaging solutions, meeting all the strict requirements of the market.

With many years of experience in the industry, Hoang Gia Printing owns a modern machinery system and a team of skilled technicians, providing high-quality processing services such as embossing, laminating, hot stamping, die-cutting and box gluing. Not only focusing on quality, the company also optimizes costs and production time, ensuring fast progress for orders from small to large.

The motto “Quality creates reputation” has helped Hoang Gia Printing constantly develop, improve processes and apply advanced technology. Customers coming to us not only receive delicate, durable paper box products but also experience professional, dedicated service from consulting, design to complete production.

Hoang Gia Printing is proud to be a trusted partner of many businesses in Hanoi, providing high quality packaging solutions, helping to enhance brands and promptly meet the growing market demand.

Contact Hoang Gia Printing now for support and advice on printing services and paper box processing in the most detail. For all contact information, please visit:

- Website: https://inhoanggia.com/

- Hotline: 0981.022.044

Nguyễn Hoàng Nam – 11 năm kinh nghiệm in ấn, sẽ giúp bạn có được bản in đẹp nhất và nhanh nhất. Liên hệ ngay cho tôi 0981.022.044

0981.022.044

0981.022.044

Chat Zalo

Chat Zalo